3 Dimensions

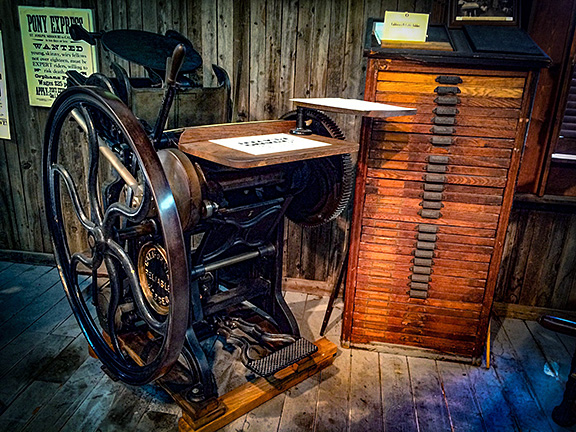

It has been speculated that one of the great leaps in human history was the printing press – movable. It put books, and therefore learning, into the hands of the vast majority of the world who otherwise would never have had it. Once exposed to learning, more and more brains were set to tackle the challenges of the world – and innovations occurred with increasing speed.

Over time, printing became cheaper and cheaper, the processes less involved – and now you can “print on demand” if you’ve written a book, or send copy to your local office supply to print business cards, brochures, or posters.

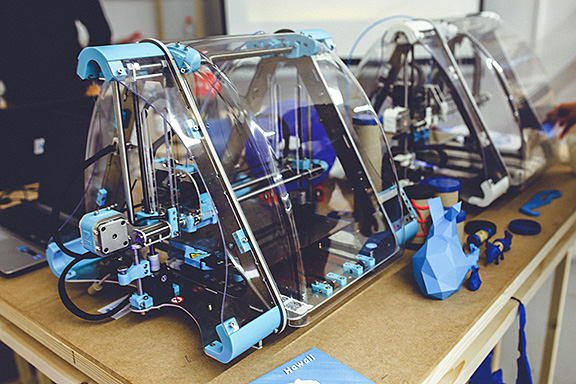

Most of us have a printer (or two) in our homes that can print articles, photos, large format, even edge to edge. And some of us have already invested in 3D printing capability, generally as a diversion more than for any purposeful activity.

I’ve seen 3D printing happen, and it is rather remarkable to watch an object take shape as, layer by layer, and under computer control, material —such as liquid molecules or powder grains— are laid down and fused together to eventually create a solid, 3 dimensional “thing.” In the early days, the 1990s, 3D printing was used mainly for prototyping, an improvement over slower hand created models of a final product, but still relatively slow and prone to error. By 2019, “precision, repeatability and material range have increased to the point where some 3D printing processes are considered viable as industrial-production technology, whereby the term additive manufacturing can be used synonymously with 3D printing.” (Wikipedia) The distinction is made between “additive manufacturing” and “subtractive manufacturing,” as the latter often used machining to remove pieces of the original material to create the shape required for the final product.

Ink jet printers were the model for the first 3D printers, as they deposit a bit of ink onto the surface of paper in a pattern controlled by the computer the printer is connected to – creating text or pictures as required. By using an ink jet type head, other materials can be deposited, layer by layer, onto a surface or template —again, computer controlled— to form a basic object.

The technology actually began development, in fits and starts in the early 1980s, and by 2014, 3D printing had evolved to include multi-material, complex objects. “As of December 2017, additive manufacturing systems were on the market that ranged from $99 to $500,000 in price and were employed in industries including aerospace, architecture, automotive, defense, and medical replacements, among many others. For example, General Electric uses high-end 3D Printers to build parts for turbines. Many of these systems are used for rapid prototyping, before mass production methods are employed. Higher education has proven to be a major buyer of desktop and professional 3D printers which industry experts generally view as a positive indicator. Libraries around the world have also become locations to house smaller 3D printers for educational and community access. Several projects and companies are making efforts to develop affordable 3D printers for home desktop use. Much of this work has been driven by and targeted at DIY/ Maker/enthusiast/early adopter communities, with additional ties to the academic and hacker communities.” (Wikipedia)

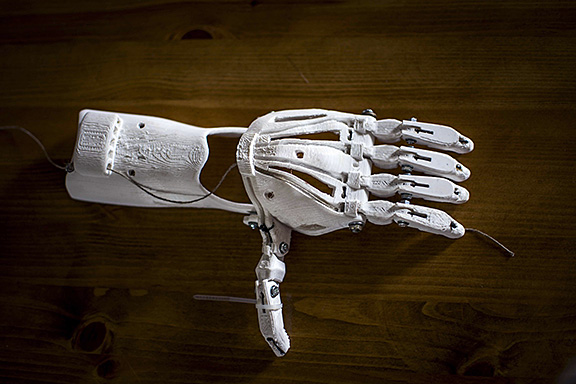

The possibilities for the technology are mind-boggling, and it has already been introduced into food production, clothing design and production (think of the lasts that a cobbler would use, one pair for each customer’s feet, so that shoes would fit that individual perfectly), replacement parts made to order, artifact restoration, and medical applications.

Needless to say, there are challenges aplenty with such technology: intellectual property, dangerous objects (guns and other weapons, for example), hazardous materials, and robotic replacement of human labor.

Lately, soft, flexible objects have been created using 3D printing, which opens yet another door to invention. But by far the most astounding —and potentially scary— use of the technology was one I saw demonstrated recently: replacement body parts. Some that will bring joy are things like an antibacterial replacement tooth, skin, and wear-proof “bone” for joint and other bony tissue replacement. Bionic eyes and ears have been created, as have other more intimidating parts like a heart, and even ovaries. These printed body part replacements are generally still in the development stage. But as with most technology, the future will no doubt look very different when we’re there than as we gaze forward in wonder.